Contrails ! Rotax 914 fuel pressure regulator

Discussion

The Rotax 914 turbocharged engine demands a precisely calibrated fuel pressure.

A discussion occured on the Europa Kitplane list, as to the regulator ability to maintain the required pressure in all circumstances. Rotax calls for airbox pressure plus 0.25 bar.

Results of our investigation will be regularly updated on this webpage.

Fuel pressure regulator

Origin

Rotax does not state the origin of the fuel pressure regulator.

The model seems to be current in racing car accessories stores.

It could be a "200" series, single membrane model from Officina Meccanica Malpassi, with specifications as follow :

TURBO FUEL REGULATOR (CARBURETTOR)

Pressure Range 60 psi in 5-7 psi out + Boost

Operation

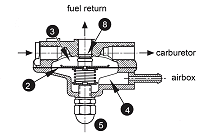

The fuel pressure regulator is installed on the airbox with two 6 mm screws (10 mm hex head).

A diaphragm (2) divides the regulator body into two compartments, the first (3) is in contact with the fuel, the other (4) is connected to the airbox.

The spring, factory preset with setscrew (5), adds its pressure (equivalent to 0.25 bar), to the airbox pressure on the diaphragm. On the other side, fuel pressure corresponds to airbox pressure plus 0.25 bar.

Excess fuel flow (on the order of 100 L/h) returns back to fuel tank via cone valve (8), controled by the diaphragm. Fuel pressure is so maintained at about 0.25 bar above airbox and carburetor float bowl pressure.

Pending question

Some Europa kit builders raised questions about the fuel pressure regulator. They are worrying wether with certain setups, the pump flow could exceed the regulator capacity, allowing fuel pressure to overcome the carburettor needle valves, leading to too rich a mixture.

The only way to be sure is to take some measurements

Hard numbers

Here are some measurements which could help to sort out this regulator issue :

(To be performed with main pump, boost pump, both pumps)

- Flow through return line, no pressurization

- Flow through return line, 0.35-0.40 bar pressurization

- Control of fuel pressure at the regulator in each of the above cases

Actual numbers

Here are some flow numbers we took on a Dyn'Aero MCR 4S with Rotax 914.

Flow through return line, no pressurization

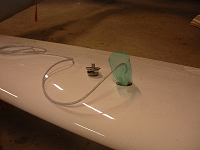

A 7-8 m long, 6 mm diameter hose was connected at the fuel return line fitting, to transfer fuel from one wingtank to the other.

The transferred fuel is filtered (5 microns) at the tank opening.

The Rotax 914 Maintenance Manual states that the flow through the regulator is on the order of 100 liter per hour.

Results

The takeoff power flow percentage is shown between brackets (33 L/h). The FAR 23 calls for a minimum of 125 %.

Battery had not been flown for two weeks. Transfer from right wingtank to the left.

Main pump : 78 L/h (236 %)

Boost pump : 80 L/h (242 %)

Both pumps : 100 L/h (303 %)

It was observed that the 8 m hose limits fuel flow : with only 3 m and a freshly charged battery, the boost pump flow values are 88 L/h, (266 %) on the right tank and 92 L/h, (278 %) on the left tank.

These numbers are superior to those taken at the time of the first flight (53 L/h, 160 %), which can be explained by the pumps running in.

Auxiliary battery endurance

The Rotax 914 fuel pumps demand a true redundant electric supply. This is why the boost pump is directly fed by the Aux battery.

During the above tests, we transfered 80 L of fuel from the right wing tank to the left and back with the boost pump, which ran flawlessly during 1 h 53 on the Aux battery alone.

In case of general electric failure, we can rely on more than 1 h 30 electric emergency endurance to keep the engine running.

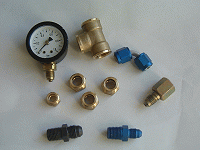

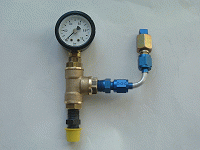

Pressure gauge installation

A few ordinary fittings to install the fuel pressure gauge. The gauge was borrowed from our favourite kit manufacturer.

Cost of the brass fittings : 4,45 €.

The setup will be installed on the fuel inlet line, to measure the regulated fuel pressure.

To learn more

Officina Meccanica Malpassi (Seregno, Italie)

Malpassi fuel pressure regulators website

Malpassi fuel pressure regulators website

E-mail me

E-mail me

Previous

Previous