Contrails ! Jabiru rocker lubrication

Rocker chamber lubrication

It would seem that some Jabiru owners have experienced valve guide and rocker difficulties. Jab owner Martin from St Tropez is sharing his findings on rocker and valve lubrication on his Jabiru 2200 tailwheel aircraft.

NB : This subject is a bit old now (2020), as Jabiru engines are less numerous.

Martin's article

taildragger findings

I would like to share some facts about my engine (2200 w/hyd lifters) and maybe get some answers from those who have already been there.

I have just completed reassembling my engine after replacement of all valve guides (both of #2 were completely worn out at 100hrs, others were replaced as precaution).

Today I started it and run for 5 min at 1200-1500 rpm, then stopped and made a close inspection.

When I removed tappet covers, I discovered there was some oil, as it should be the case, in rear rocker chambers (# 3 and 4) but the forward ones were AS DRY AS PRIOR TO ASSEMBLY.

The airplane was sitting almost level, with tail slightly lower, maybe 5°. Oil level was slightly above minimum, as per SB 013-1.

Oil pressure

My oil pressure has always been on the low side although within specs (35-40 psi, curiously pretty stable at cruise, idle, hot and cold). I fly with oil cooler (oil temp around 80°C (180F)). I flew for a while without the cooler and without adapter but that was in winter. Oil temp were then around 100-110°C in a long climb and there was a slight drop in oil pressure, maybe down to 30 psi.

I also suspected this as being responsable, and I have just modified the adjustment of the pressure regulator. I now get 70 psi right after starting and then within one-two minutes it stabilises at 60 psi. BUT NO CHANGE TO OIL DISTRIBUTION IN HIGHER/LOWER HEADS.

Aircraft attitude

After checking that the T junctions on oil feed line were not blocked and some more thinking, I tilted the airplane more on the nose (3° nose down), cleaned rocker chambers and run it again for 1 min at 1200 rpm.

This time forward rocker chambers were correctly flooded with oil while the aft ones were virtually dry, except a few drops. I sincerely hope that at a higher power setting the amount of oil carried thru the feed tube from under the cylinders is sufficient to spread it correctly in the T-junction to grease both rocker chambers (I have so far always seen oil in rocker chambers, although there was always more of it in the rear ones (my plane is a taildragger).

But the worrying truth seems to be that when warming the engine or taxiing at low rews (and even more so in a taildragger, although already 5° tilt seems to make a difference), there are good chances that fwd cylinder rockers and valve guides run dry !!!! My guess is that the quantity of oil delivered is insufficient and it only runs "down the slope", towards the cylinder that is lower.

This could be by the way one of the possible explanations why my valve guides were ruined after 100 hrs and that my rocker bushings also show some premature wear.

Once at that subject, the SB 013-1 explained to us that vent holes and correct routing of the sump breather were supposed to enhance the return of oil from rocker chambers back to the sump, as if too much oil was delivered to the heads. Seemingly, I have the opposite problem (or at least I do have it on lower revs)

Isn't there a restriction between the main oil galley and the two tubes feeding oil to rocker chambers, that could be increased ????

Glass rocker covers

I ended up by making two glass rocker covers so I can run the engine AND SEE what the oil is doing.

If only the aircraft is 5° out of horizontal, ONLY THE LOWER HEAD GETS OIL.

When you look into the rocker chamber you will find out that even in that lower head the only valve and valve rocker that gets oil is the intake one (on a 2200), as it is next to the oil delivery tube.

The exhaust valve on the opposite side of the rocker box doesn't get any direct lube. There is no oily fog under rocker covers like in all engines I have seen in my life.

So even trigears could be concerned, if you climb to 10000 ft, that's 20 min nose-up attitude and your fwd heads don't get much lube...

Additional tests

Some more tests I did:

1. I ran my engine (tail on the ground, perspex covers to see boxes) and tried to create some vacuum in the breather, by connecting there a vacuum cleaner - no change, fwd box still dry.

2. I drilled 2 mm holes in perspex covers (I normally have holes on my regular covers to comply with JSB13-1) - no change

3. I put vacuum cleaner tube against the hole in perspex (fwd box), creating some depression in the box - some oil ingress, but marginal.

4. Running the engine with aft cover on and fwd off created an immediate oil ingress in higher box - exactly as described by Kurt.

5. Same experience with both perspex covers on, the hole on the aft one blocked with a finger - fwd box gets a little oil but much less spectacular than 4.

I took some precise measures (engine running 1200-1400 rpm, oil cold, oil pressure at 4 bar (60 psi), level around minimum as per JSB13-1.

6. One rocker lube tube (that brings up oil from the main galley to rocker boxes) was disconnected from its Tee and connected instead to an additional pressure gauge. The engine was started.

Pressure in this tube was raising very slowly (engine oil system was at 60 psi, and the gauge at the lube tube reached 0.5 bar (7 psi) after 1 min, 1.5 bar (20 psi) after 2 min, 2.3 bar (30 psi) after 3 min and 2.8 bar (50 psi) after 4 min.

Test was stopped at that point to avoid too much torture to the engine. Slow oil buildup was certainly due to a timid oil flow.

7. Both lube tubes were disconnected from the Tees and re-routed to a jug and the engine started. The quantity of oil pumped out at 1200-1400 rpm from BOTH tubes was the equivalent of 2 liters (0.54 USgal) per hour, that is 0.5 l/h per head.

Projected mods

As for the actual way the lube system is conceived, the tube that carries up oil from the main gallery to rocker boxes has (in my engine at least) a 2 mm restriction.

I think rockers and valves would get an easier life if the system was as follows :

1. you get rid of that restriction, and

2. the tube splits in two, to go separately to fwd and aft heads, and

3. the ends of these two tubes have restrictions (perhaps something around 1.5 mm) that would act like jets, delivering oil under pressure to each rocker box.

I presume that this injection effect could also create a more foggy environment, for a better lubrication and cooling of BOTH valves and BOTH rockers.

Such a mod could be relatively easy to carry out. Definitely easier that changing valve guides and rockers/shafts every 100 or 200 hrs...

Modification update

Today I carried out the projected oil line modification.

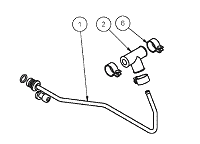

The restrictor at the bottom of the oil feed line [1] was removed (initially a 2 mm diameter orifice was controlling the amount of oil delivered to the cylinder heads).

The original rubber Tee [2] was replaced with a bronze one. The two horizontal branches of this Tee feeding oil to the the cylinder heads were fitted with restrictors (1.6 mm diameter, but I think they should be smaller).

The idea is to keep the oil under pressure up to the top of the feed line [1], so that is is "injected" into the upper as well as the lower head (when the engine is not level, as in a climb or when starting up a taildragger).

Naturally I did the same on both sides of the engine.

It works !!!

The difference is dramatic ! After the mod, oil appears simultaneously at the FRONT as well as the REAR head 35 seconds after a cold start, whereas before the upper head did not get a single drop of oil.

I am still a bit unsatisfied though, as I was hoping that once warmer and thinner, this "injected" oil would be sprayed into the head, improving the valve and guide lubrication (they are splash lubricated).

On the contrary, certainly due to the limited oil flow, the distribution effect between heads is reduced when the oil is warmer, and no atomization.

But it still is an improvement upon the original setup !!!

Videos

Valve guide wear

Comparison between exhaust and inlet valve guide wear at 100 hrs.

The actual valve lifts are approximately reproduced.

Valve lubrication BEFORE mod

Rocker chamber lubrication BEFORE oil supply Tee modification.

Only the lower (rear) head gets oil.

Oil supply to valves AFTER mod

Oil supply to upper heads when hot AFTER oil distribution Tee and restrictor changes.

The upper head gets about as much oil as the lower one.

Any comments ?

Martin

To learn more

Jabiru rocker lube follow-up

Jabiru France

Send an email

Send an email

Jabiru France

Jabiru France