- Home

- Electricity

- Rotax alternator

Contrails ! The Rotax 912/914 alternator

An experimental study

During the construction of the MCR4S, many questions circulated about the electrical generation of Rotax motors.

In order to clear things up, I was able to get my hands on a complete Ducati/Rotax alternator.

Jérôme Delamare, an electrical researcher at the University of Grenoble Alpes (G2Elab), then offered to help me with an in-depth study.

We conducted these investigations during the winter of 2003-2004.

Characteristics

The alternator

The alternator mounted on the Rotax engines is made in Italy by DUCATI energia.

It is a permanent magnet single-phase alternator.

It is therefore necessary together to rectify its AC voltage to transform it into DC voltage, to smooth it to obtain a constant voltage, and to regulate it around 14 Volts.

For this, it is first necessary to know the characteristics of the alternator.

Most of these characteristics were not found in the manufacturer's documentation, so we measured them.

- Power: 250W (258W/12.6V/20.5A regulator output @ 5800 rpm)

- Rotation speed: 1000 to 6000 rpm

Manufacturer data:

Characteristics determined in the lab:

- Single-phase: without midpoint or connection to ground

- Weight: 2.3 kg (stator 700 g, rotor 1.6 kg)

- Number of pole pairs: 5

- Stator resistance: 0.12 Ohm (at 20°C)

- Inductance : 750 µH

- Electromotive force:

- 1/60 V/(rpm) peak

- 1/120 V/(rpm) effective

- Max short-circuit current: 21 A effective at 150 Hz

- Output frequency: 83 Hz to 500 Hz

- Output voltage: 16 V to 100 V peak

Measurements at G2Elab (Univ Grenoble Alpes)

Test bench

A machined adapter and a ball bearing were necessary to install the alternator on a test bench at G2Elab.

The assembly allows the rotation of the rotor (outside) while immobilizing the stator with a metal finger engaged in one of the holes in the stator.

A metal guard is mounted on the bench to protect against the alternator possibly going ballistic ;-)

Measurements

The alternator is driven by a DC motor (in gray).

Electrical cabinet and mobile power source.

Oscillogram of the alternator no-load output voltage.

Not very appealing...

NB : The frequency is used to determine the rotation speed.

200 Hz with 5 pairs of poles corresponds to 40 rev/s, i.e. 2400 rpm.

Modelization

Spectral analysis

In order to simulate the alternator, a spectral analysis allowed us to obtain a harmonic decomposition of the no-load voltage.

Using less technical terms, this means that we will be able to trace this curve by superimposing several sinusoids of different frequencies.

At 102 Hz, for an effective voltage of 10.56 V, we obtain the following harmonic decomposition in effective value:

| Harmonic 1 : | 10 | V | 100 Hz | 0° | ||

| Harmonic 3 : | 3 | V | 300 Hz | 180° | ||

| Harmonic 5 : | 0.21 | V | 500 Hz | 0° | ||

| Harmonic 7 : | 0.65 | V | 700 Hz | 0° | ||

| Harmonic 9 : | 0.59 | V | 900 Hz | 180° |

We then consider that the no-load voltage is proportional to the frequency.

Simulation of the 200 Hz no-load voltage with the above values gives a result very close to reality (compare with experimental curve in previous paragraph).

Discussion

In normal operation, the regulator components will therefore be subjected to an alternator voltage of 100 V at 6000 rpm.

This value must not only be used to size the electronic components of the regulator, but reminds us that overvoltage protection might be a useful safety feature.

In case of regulator failure, this voltage could cause some damage if it found its way to the on-board network…

The effective voltage as a function of the speed of rotation can then be easily traced:

![]()

Impedance

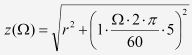

The alternator has an internal impedance. It can be modeled by a resistance in series with an inductance.

Resistance

Resistance was measured by a voltammetric method by feeding the stator with a (reduced) DC voltage: 0.12 Ohm at 20° C.

Inductance

The inductance was measured by different methods:

| • | Impedance bridge: | 200 | µH |

| • | By supplying the stator under reduced voltage: | 400 | µH |

| • | By measuring short-circuit current: | 750 | µH |

The first measurement was made with a current of a few mA, the second with a current of a few amps and the last with a current of 21 A.

These differences in inductances are certainly due to the saturation of the stator magnetic circuit by the rotor magnets.

When the alternator produces current, the field created by the stator winding opposes the magnetic field of the rotor and reduces saturation.

As we will see later, the instantaneous current delivered by the generator is important.

We will therefore retain 750 µH for the inductance

Electric modelization

The complete electric model of the alternator is therefore as follows (given at 200 Hz, i.e. 2400 rpm)

It is then possible to trace its impedance and short circuit characteristics.

Characteristic curves

Impedance

As shown by these curves, the influence of resistance is negligible above 1000 rpm.

It is therefore the inductance which will limit the alternator current.

Short-circuit current

![]()

The inductance has an impedance which is proportional to the frequency.

The open circuit voltage of the alternator is also proportional to the frequency.

The short-circuit current is therefore constant whatever the speed, as soon as the resistance is negligible compared to the inductance.

We measured a short-circuit current of 21 A.

Alternator protection

Question

Can the alternator withstand this current of 21 A or must it be protected against over currents?

Temperature measurements

To answer this question, we ran it in short circuit, equipped with a temperature probe placed on the surface of the stator winding.

It not only allow to read the temperature, but also to ensure that we remain in a safe winding operating range.

During this short circuit test, a temperature rise of 30°C is noted on the surface of the winding. This temperature stabilizes after 25 min of operation.

After stopping the test bench, the surface temperature rose an additional 17°C in 45 seconds.

Interpretation

This rise in temperature is due to the heat stored in the center of the windings.

When stopped, the air flow caused by the rotor disappears.

As the winding surface is no longer cooled by forced convection, the outside temperature of the winding becomes substantially equal to its inside temperature.

Under our test conditions, it is therefore possible to estimate a stator short circuit temperature rise of 50°C.

In real operating conditions, assuming an ambient temperature of 80°C and keeping the same assumptions, the winding would then operate around 130°C.

A low-end winding insulation easily withstands 150°C…

Reassuring values

We can rest assured, knowing that each time, the assumptions taken are very conservative.

The heat will be better rejected by conduction through the housing of the ROTAX than by the running of our test bench, ambient air temperature might very well be below 80°C, and the insulation of the winding is not necessarily poor quality.

NB : we observe that despite the "tortures" undergone at full power for weeks, the winding insulation still in perfect condition (Cf. fontispice).

Thermal imaging

Jérôme's Licence Pro students used a thermal camera for studying the voltage regulator.

The images of the Ducati/Energia alternator at full power are very telling.

The eight generation windings gradually heat up, while the two ignition windings remain at room temperature.

Their operation has not been characterized, due to their low consumption, and their electrical separation from the generation circuit.

Conclusion

In summary

So the alternator is inherently protected by its short-circuit current and its thermal characteristics.

The only precaution is to size the cables to pass 20 A between the alternator and the voltage regulator.

Email the author

Email the author